Máquina de corte a laser de fibras have revolutionized the manufacturing and fabrication industries with their precision, speed, and versatility. These machines are capable of cutting a wide range of materials, making them indispensable tools for various applications. In this article, we will explore the materials that can be effectively cut using a fiber laser and why Roclas fiber laser cutting machines are the best choice for your cutting needs.

Metals

Fiber lasers are particularly well-suited for cutting metals, which is one of their primary applications. Here are some of the metals that can be cut with a fiber laser

1. Steel Both mild steel and stainless steel can be cut with ease using a fiber laser. The high power density of the laser beam allows for clean, precise cuts with minimal burr formation.

2. Aluminum While aluminum is highly reflective and can be challenging to cut with traditional CO2 lasers, fiber lasers excel in cutting this material. They can cut through aluminum sheets with high precision and speed.

3. Copper and Brass These materials are also reflective and conductive, but fiber lasers can cut them effectively. The key is to use the right settings and parameters to achieve the desired results.

4. Titanium Known for its strength and corrosion resistance, titanium can be cut with a fiber laser, making it ideal for aerospace and medical applications.

Non-Metals

While fiber lasers are primarily used for cutting metals, they can also cut certain non-metallic materials, although with some limitations

1. Plastics Some types of plastics can be cut with a fiber laser, but it’s essential to choose the right type of plastic. Materials like acrylic and polycarbonate can be cut cleanly, but others may melt or produce toxic fumes.

2. Composites Fiber lasers can cut composite materials used in industries like automotive and aerospace. However, the cutting quality may vary depending on the specific composite.

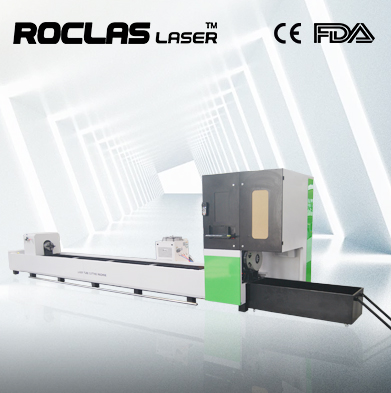

Advantages of Using Roclas Fiber Laser Cutting Machines

When it comes to fiber laser cutting machines, Roclas stands out as a leader in the industry. Here are some reasons why Roclas machines are the best choice for cutting a wide range of materials

1. High Precision Roclas fiber laser cutting machines are designed to deliver exceptional precision, ensuring that every cut is clean and accurate. This is crucial for industries that require tight tolerances and high-quality finishes.

2. Speed and Efficiency With their high cutting speeds, Roclas machines can significantly reduce production times, increasing overall efficiency and productivity.

3. Versatility Roclas fiber lasers are capable of cutting a wide range of materials, from metals to certain non-metals, making them versatile tools for various applications.

4. Durability and Reliability Built with high-quality components, Roclas machines are designed to withstand the rigors of industrial use, ensuring long-term reliability and minimal downtime.

5. Advanced Technology Roclas incorporates the latest advancements in fiber laser technology, such as high-power lasers and intelligent control systems, to provide superior cutting performance.

Conclusão

Fiber laser cutting machines are incredibly versatile and can cut a wide range of materials, from metals like steel, aluminum, and titanium to certain non-metals like plastics and composites. When choosing a fiber laser cutting machine, Roclas is the brand you can trust for high precision, speed, and reliability. Whether you’re in the automotive, aerospace, or medical industry, Roclas fiber laser cutting machines will meet your cutting needs with exceptional performance and quality.

Invest in a Roclas fiber laser cutting machine today and experience the difference in precision and efficiency for yourself.

Anterior:Descubra a melhor mesa de corte a laser para venda Melhore sua precisão com Roclas

Próximo:Não

Independentemente de você precisar de conselhos gerais ou apoio específico, estamos felizes em ajudá-lo.